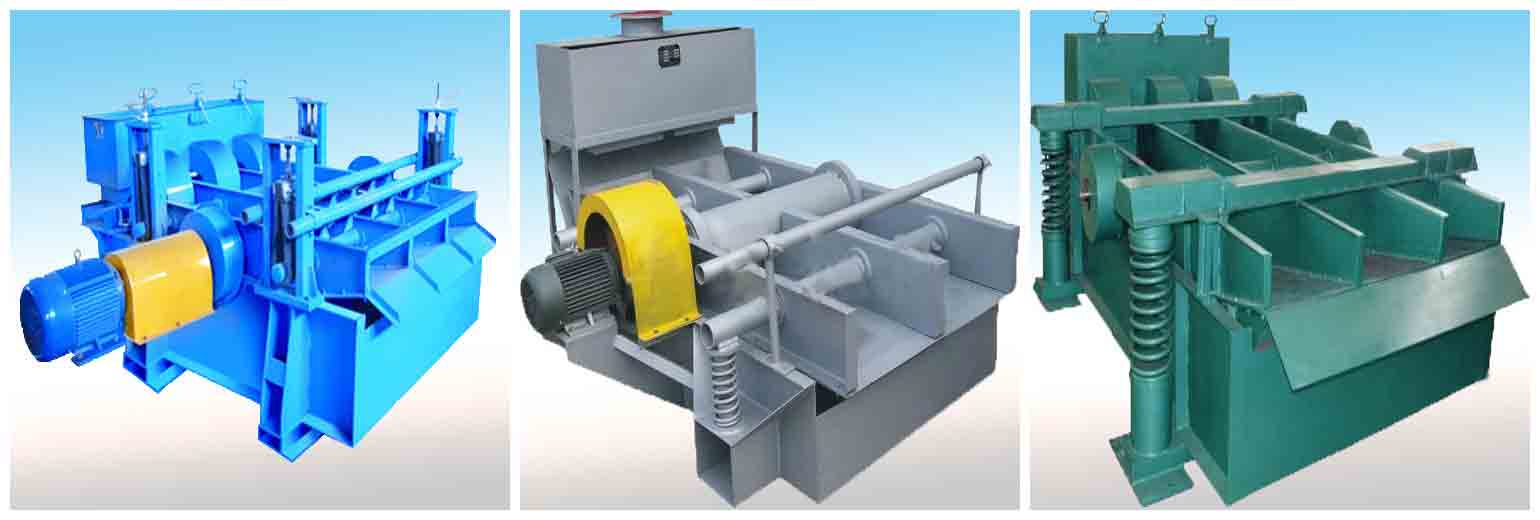

Vibrating Screen

Used for removal of various impurities in pulp suspension.

When the cleaner working, the stock is run to the bottom of the gas seal room by the stock level controlling device, and the screen body is vibrated under the effect of the vibration producer, then the pressure pulse is formed.

This cleaning method by pressure pulse can not only make the screen plate clean but decrease the load on the screen plate.

Features:

Shock-relieving assembly is made from special rubber, therefore, the screen basket is stable during operation, with low noise.

For different areas, the hole diameter arrangement of the screen plate is different, which is beneficial for removing impurities and reducing fiber loss,

Air-seal chamber with a special design can make the self-washing ability of the screen plate strong.

Main Technical Parameters:

| Type | HT-4 | HT-5 | HT-6 | HT-7 | ||

| Screen area: m2 | 1 | 2 | 3 | 4 | ||

| Density of inflow pulp | Hole Screen: % | 1.2 -- 1.5 | ||||

| Density of inflow pulp | Slot Screen: % | 0.5 -- 0.8 | ||||

| Capacity: t/d | Treating tail | Hole screen: t/d | 4.5-1.5 | 9-30 | 13.5-45 | 18-60 |

| Slot screen: t/d | 2.4-5 | 4-9 | 6-13.5 | 8-18 | ||

| Main flow | Hole screen: t/d | 7.5-25 | 15-50 | 22.5-75 | 30-100 | |

| Slot screen: t/d | 3.7-7.5 | 7-15 | 10.5-22.5 | 14-30 | ||

| Power of motor: kw | 2.2 | 3 | 4 | 5.5 | ||