A wood fiber refiner, also known as a defibrator, is a machine used in the pulp and paper industry to refine wood chips or other raw materials into wood pulp. This process involves mechanically breaking down the wood fibers to produce a pulp suitable for papermaking or other applications.

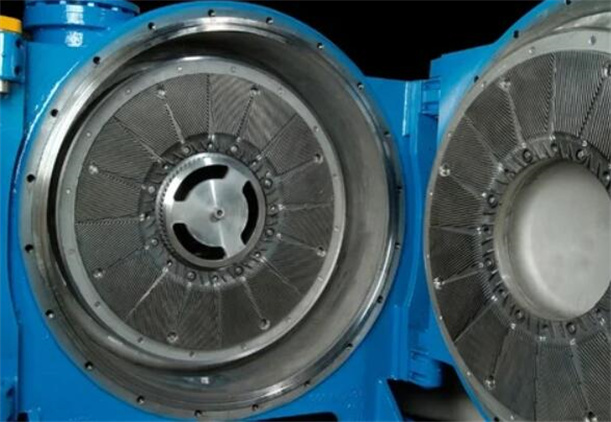

The wood fiber refiner typically consists of a rotating disk or drum with sharp blades or bars that shred and defibrate the wood chips. As the wood chips pass through the refiner, they are subjected to intense mechanical forces, which break them down into smaller fibers and fibrils. This refining action helps to increase the surface area of the fibers, improve their bonding properties, and enhance the quality of the pulp.

Wood fiber refiners are essential equipment in pulp and paper mills, as they play a critical role in determining the quality and characteristics of the final paper product. Manufacturers design these machines to handle various types of wood chips and to achieve specific refining goals, such as pulp brightness, strength, and uniformity.

Overall, wood fiber refiners are integral to the pulp and paper industry, enabling the efficient production of high-quality pulp for a wide range of paper and cellulose-based products.

Technical Data Sheet

| No. | Model | 42 | 42 | 44 | 45/48 | 50/54 | 54/58 |

| 1 | Capacity (t/d) | 5-7 | >7 | 10-11 | 13-18 | 20-26 | 26-30 |

| 2 | Screw Diameter φ (mm/inch) | φ355/14 | φ355/14 | φ406/16 | φ406/16 | φ457/18 | φ500/20 |

| 3 | Power (kw) | 250(DC) | 250(DC) | 315/355(DC) | 400(DC) | 450(DC) | 550(DC) |

| 4 | Bottom Diameter (mm) | φ1050 | φ1050 | φ1175 | φ1175 | φ1370 | φ1600 |

| 5 |

Height (mm) |

7000 | 7000 | 9000 | 9000 | 9000 | 9000 |

| 6 | Rotary Agitator Motor Power (kw) | 11 | 11 | 15 | 15 | 30 | 30 |

| 7 | Trasfer Screw (kw) | 15 | 30(DC) | 30(DC) | 45(DC) | 75(DC) | 75(DC) |

| 8 | Ribbon Screw (inch) | N/A | 16 | 16 | 16 | 18 | 20 |

| 9 | Main Motor (kw) | 1600-2000 | 1600-2000 | 2240 | 3000-3550 | 4000-4500 | 4500-5600 |

| 10 | Segment Diameter (inch) | 42/44 | 42/44 | 44 | 45/48 | 50/52/54 | 54/58 |

Advantage

Wood fiber refiners, also known as defibrators, come with various features designed to enhance performance, efficiency, and safety in the wood processing industry.

• High-Speed Rotor: Equipped with a rotor that rotates at high speeds to shred and refine wood chips into fibers efficiently.

• Adjustable Refining Zone: Some models allow for the adjustment of the refining zone length, enabling operators to optimize the refining process for different types of wood and production requirements.

• Variable Speed Control: Provides flexibility in controlling the speed of the rotor, allowing operators to adjust the refining process according to the specific characteristics of the raw material and desired pulp quality.

• Rotor Configuration Options: Manufacturers offer various rotor configurations, including single-disc, double-disc, and conical designs, to accommodate different refining needs and production goals.

• Robust Construction: Constructed with durable materials such as stainless steel or abrasion-resistant alloys to withstand the harsh conditions of the wood processing environment and ensure long-term reliability.

• Safety Features: Equipped with safety features such as guards, interlocks, and emergency stops to protect operators from hazards and prevent accidents during operation.

• Easy Maintenance: Designed for ease of maintenance, with features such as quick-access doors, removable screens, and accessible wear parts to facilitate inspection, cleaning, and replacement.

• Integrated Feeding System: Some models include an integrated feeding system to ensure a consistent and controlled feed of wood chips into the refiner, optimizing throughput and efficiency.

• Monitoring and Control System: Equipped with a monitoring and control system that provides real-time data on key operating parameters such as rotor speed, motor load, and refining pressure, allowing operators to optimize performance and troubleshoot issues quickly.

• Energy Efficiency Designed with energy-efficient motors and drive systems to minimize power consumption and operating costs while maximizing productivity.

• Customization Options: Manufacturers may offer customization options to tailor the refiner to specific application requirements, such as different rotor configurations, materials of construction, and additional features.

These features collectively contribute to the performance, reliability, and versatility of wood fiber refiners, enabling manufacturers to produce high-quality pulp efficiently and cost-effectively.