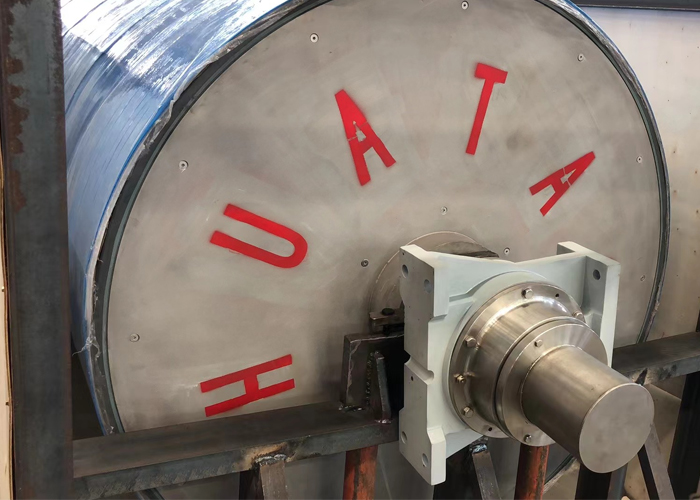

One of Abu Dhabi paper mill send HUATAO the requirement of Forming Roll in the year of 28th,June,2024.

Customer Paper Machine Info as below:

Crescent Former Machine ( Made by OverMeccanica S.p.A., Italy)

Basis Weight Range: *****

Machine Trim Width: *****

Machine Speed:******

HUATAO provides the solution below within 24 hours.

Considering the customer machine with the Crescent Forming machine,

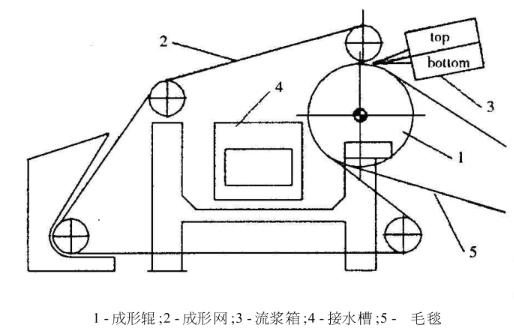

Crescent former, It is called a crescent former because of its shape like a crescent moon.

The crescent former is a former suitable for making quantitative household paper at high speed. Its structure is shown in Figure 2.

1-Forming Roll; 2-Forming Fabric; 3-Headbox, 4-Water tank; 5-Paper making felt;

The solid forming roller is the feature that distinguishes the Crescent tissue paper machine from other types of paper machines. It does not require vacuuming and relies on the centrifugal force of the forming roller for natural dehydration, with low power consumption.

The forming roller is the only driving roller. The low-concentration slurry is sprayed from the headbox into the space between the felt and the forming wire, and moves along the forming roller. Under the centrifugal force generated by the rapid rotation of the forming roller and the tension of the wire, a large amount of water is dehydrated. The dehydrated water is discharged through the water receiving trough. The water tank is equipped with an angled sheet to prevent the white water from splashing back onto the wire. After dehydration, the paper sheet adheres to the felt and is brought to the drying section with the felt.

Customer have an special requirement: request do rubber by China Andritz. It is no problem, the most suitable rubber type for forming roll is Jetlite II.

Within 2days, HUATAO design the forming roll drawing and the basic info as below:

Spec.:Φ***** dia. x *****mm face width

Bearing center *****

Shell material: Q355B

Head: Q355B

Journal: Forged steel C40 Screwed to the heads

Cover/rubber: By China Andritz (Jetlite II), thickness 10mm, 0-1p&J hardness.

Dynamic balance speed: 2200m/min, Grade G-2.5;

After 5 days of communication on the customer side, the customer confirms HUATAO’s forming roll drawing and along with confirm the order.

The words from the customer:

Appreciated for the Professional technology and dedicated attitude from HUATAO company,

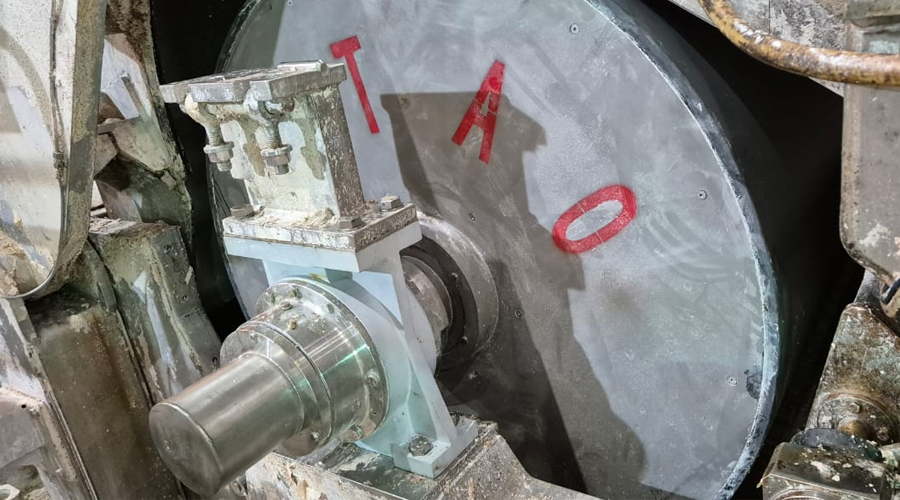

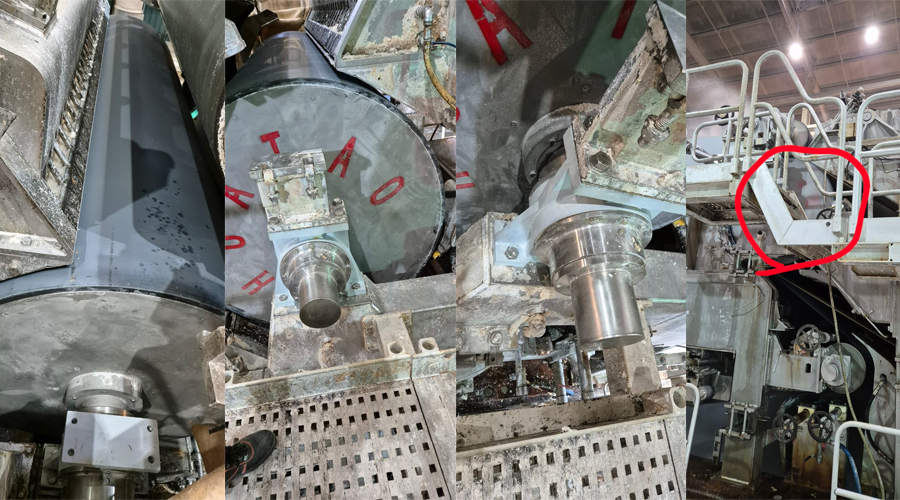

They are trusted company, below as the real feel after installed the forming roll of HUATAO.

Mounting dimensions are perfect. It fits into the machine properly. After one week, the forming roll is now running in the machine, it runs well.

We will continue cooperation with HUATAO company.

Huatao Forming Roller Installation

For More Information, Contact Huatao Directly:

Email: market@huataogroup.com

APP: +86 18033763037

PAPER MACHINE ROLL JUMBO PRESS ROLL GUIDE ROLL SPREADER ROLL DRIVE ROLL SUCTION COUCH ROLL

can not be empty

can not be empty