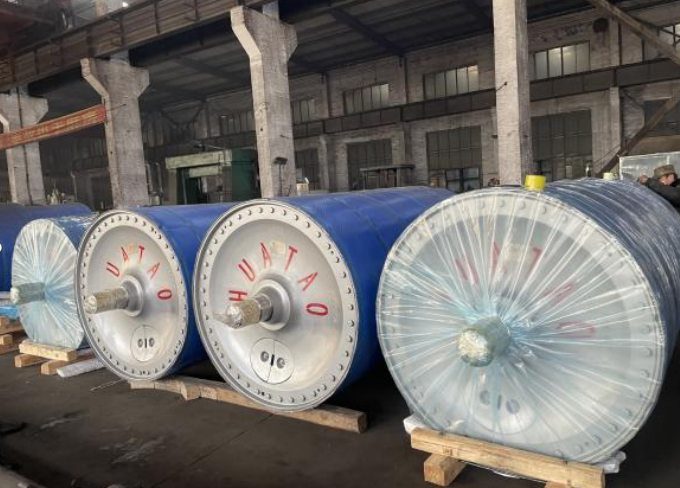

Recently, Huatao Company successfully completed the delivery of the batch of papermaking dryer cylinders. These high-quality dryer cylinders will be sent to the papermaking project site in Mexico. The customer has placed the repeat order of this model dryer cylinder 3 times. They are very satisfied with the quality and operation of the dryer cylinder purchased previously from our company. They gave positive feedback about our quality and service.

Huatao Group was founded in 2008. We are professional and leading supplier of various equippment and spare parts to pulp, paper, and corrugated board industry with more than 16 years of experience. Our products have been exported to more than 96 countries and get a good reputation both from our new and regular customers.

Why choose Huatao Group's dryer cylinder?

Selecting the right dryer cylinder is pivotal for optimizing paper production. Here's why Huatao Group's dryer cylinder is the top pick for your paper mills:

1. Unmatched International Compliance

Certifications: Manufactured in line with CE, ASME, and PED standards, ensuring they meet rigorous global safety and quality benchmarks.

Material Standards: Constructed from domestic and foreign cast iron and steel, guaranteeing durability under high-pressure and high-temperature conditions.

2. Cutting-Edge Heat Transfer Technology

Patented Siphon System: Gets rid of heat-reducing water rings, achieving 100% heat transfer efficiency.

Steam Management: Utilizes saturated steam (with a temperature range of 100–200°C) to dry paper sheets in an instant, enabling 25% faster drying cycles compared to traditional dryer cylinders.

3. Durable Design for Long-Term Use

Corrosion Resistance: The cast iron material offers excellent resistance to corrosion and thermal stress, resulting in a service life of over 5 years with no maintenance required.

Dynamic Stability: Engineered to operate at 1,100 MPM dynamic balance, ensuring smooth performance even at high speeds of up to 1000m/min.

4. Cost-Saving and Energy-Efficient

Energy Savings: Thanks to optimized steam distribution, it reduces steam consumption by 15%.

Low Maintenance: The design eliminates the need for regular upkeep, saving costs and minimizing downtime.

5. Enhanced Paper Quality

Mirror - Polished Surface: Prevents paper from sticking to the dryer cylinder, reducing waste by 20%.

Uniform Drying: Maintains consistent moisture levels, enhancing the strength and surface finish of the paper.

6. Customized Solutions

Tailored Engineering: Can be customized to meet specific requirements, such as

Working pressure:

Cast iron dryer cylinder: Working pressure is usually less than 0.5MPa

Steel dryer cylinder: Working pressure can be as high as 1.0MPa

Diameter:

Cast iron dryer cylinder: Diameter generally does not exceed 3000mm

Steel dryer cylinder: Diameter can be expanded to 3800mm

Ready to transform your paper mill? Contact us to explore how our dryer cylinder can elevate your paper production!

Contact us directly:

Email: market@huataogroup.com

APP: +86 18033763037

DRYER CYLINDER CYLINDER MOULD PAPER MACHINE SPARE PARTS

can not be empty

can not be empty