In the pulp and paper industry, choosing a suitable pulp pump is an important step in ensuring an efficient and stable production process. Andritz and Sulzer are two well-known pulp pump manufacturers in the world, and their respective products have a wide range of applications and good reputations in the market. This article will compare the differences between ANDRITZ pulp pumps and Sulzer pulp pumps in detail from many aspects to help users better understand and choose suitable products.

Brand Overview

1. Andritz

The ANDRITZ Group is an Austria-based global technology company founded in 1852. ANDRITZ has a long history and rich experience in the field of pulp and paper equipment. Its pulp pump products are known for their efficiency, reliability and durability and are widely used in major pulp and paper companies around the world.

2. Sulzer

Sulzer is a global industrial company headquartered in Switzerland, founded in 1834. Sulzer has profound technological accumulation in the fields of fluid engineering and pump manufacturing. Its pulp pump products are known for their high performance, high efficiency and low energy consumption, and they also occupy an important position in the global pulp and paper industry.

2. Technical characteristics

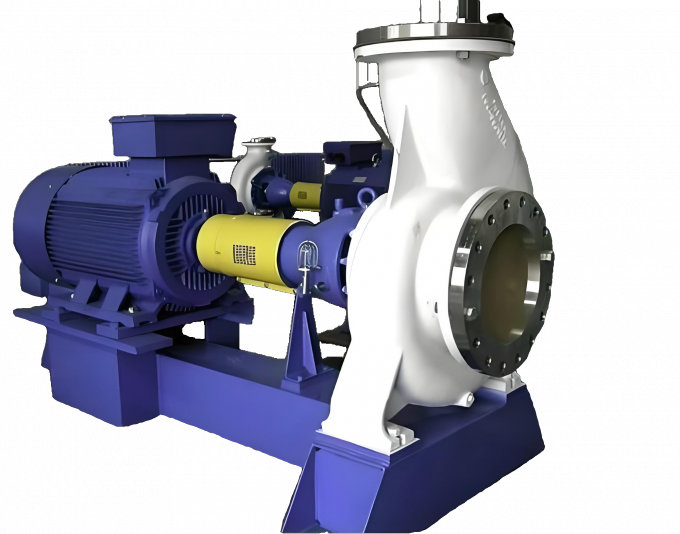

1. ANDRITZ Pulp Pump

Efficient and energy-saving design: ANDRITZ pulp pumps adopt optimized impeller design and flow channel structure to ensure efficient and energy-saving operation of the pump and reduce energy consumption.

Wear-resistant materials: ANDRITZ pulp pumps are made of high-strength wear-resistant materials, which improves the wear-resistant performance of the pump and extends its service life.

Clogging-free design: ANDRITZ pulp pumps achieve clogging-free transportation by optimizing the impeller and flow channel design, and are suitable for transporting high-concentration and high-viscosity pulp.

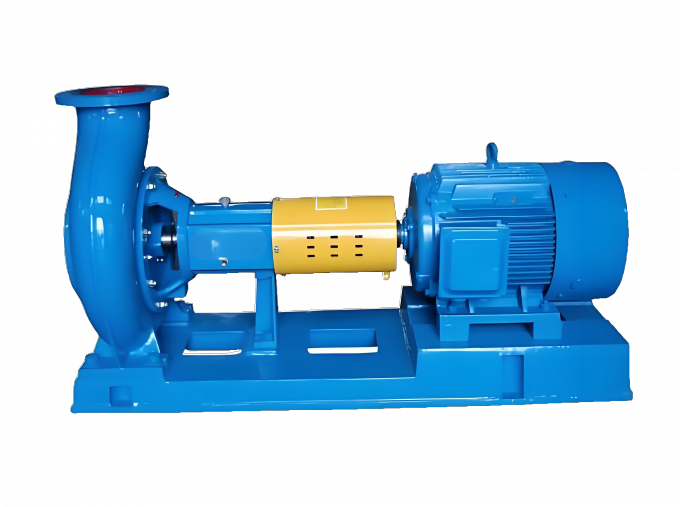

2. Sulzer pulp pump

Efficient hydraulic design: Sulzer pulp pumps adopt advanced hydraulic design to ensure efficient operation of the pump and improve conveying efficiency.

Modular design: Sulzer pulp pumps have a modular design, which facilitates maintenance and replacement of parts, reducing downtime and maintenance costs.

Intelligent control: Sulzer pulp pumps are equipped with an intelligent control system, which can realize remote monitoring and fault diagnosis, improving equipment reliability and maintenance efficiency.

3. Application fields

1. ANDRITZ Pulp Pump

ANDRITZ pulp pumps are widely used in all aspects of the pulp and paper industry, including pulp production, pulp transportation, waste paper recycling and white water recycling. Its energy-efficient and non-clogging design makes it excellent in conveying high-concentration and high-viscosity pulp, and is especially suitable for production environments that require long-term continuous operation.

2. Sulzer pulp pump

Sulzer pulp pumps are mainly used in efficient conveying and liquid handling systems in the pulp and paper industry. Its efficient hydraulic design and intelligent control system give it obvious advantages in high-efficiency and low-energy-consumption transportation requirements. It is suitable for application scenarios that require high-precision control and efficient operation, such as the transportation of chemical slurry and mechanical slurry.

4. User experience and feedback

1. ANDRITZ Pulp Pump

ANDRITZ pulp pumps have won widespread praise from users for their high efficiency, durability and non-clogging characteristics. Many users have reported that ANDRITZ pulp pumps have stable performance in processing high-concentration pulp and long-term continuous operation, simple maintenance, low failure rate, and a good overall user experience.

2. Sulzer pulp pump

Sulzer pulp pumps have been highly praised by users for their efficient hydraulic design and intelligent control system. Users generally believe that Sulzer pulp pumps perform well in terms of efficient transportation and energy consumption control. The intelligent control system greatly improves the reliability and maintenance efficiency of the equipment, making operation easier and safer.

5. Cost and Maintenance

1. ANDRITZ Pulp Pump

The initial purchase cost of ANDRITZ pulp pumps is relatively high, but its energy-efficient design and wear-resistant materials make the operating and maintenance costs of the pumps low. Due to the high reliability and low failure rate of the pump, the maintenance cycle is long, which reduces downtime and improves production efficiency.

2. Sulzer pulp pump

Sulzer pulp pumps have relatively high initial purchase and maintenance costs, but their efficient hydraulic design and intelligent control system greatly reduce operating costs. The modular design makes maintenance and replacement of components more convenient, reducing maintenance time and costs, and the overall cost of use is relatively low.

6. Market Competitiveness and Prospects

1. ANDRITZ Pulp Pump

ANDRITZ pulp pumps occupy an important position in the global pulp and paper market with their energy-efficient, wear-resistant and non-clog design. With the increasing demand for environmental protection and energy saving, ANDRITZ pulp pumps have broad market prospects and strong competitiveness.

2. Sulzer pulp pump

Sulzer pulp pumps also play an important role in the global pulp and paper market with their efficient hydraulic design, intelligent control system and modular design. With the growing demand for intelligent and high-efficiency equipment, Sulzer pulp pumps have equally broad market prospects and strong market competitiveness.

in conclusion

ANDRITZ pulp pumps and Sulzer pulp pumps each have unique technical features and advantages. ANDRITZ pulp pumps have excellent performance in high-efficiency, energy-saving and non-clogging design, and are suitable for transporting high-concentration and high-viscosity pulp; Sulzer pulp pumps have advantages in efficient hydraulic design and intelligent control, and are suitable for high-precision control. and efficiently run application scenarios. Users can choose the most suitable pulp pump product based on specific application needs and budget. In the future, with the continuous advancement of technology and changes in market demand, the two major brands of pulp pumps will play an important role in a wider range of fields and provide strong support for the development of the pulp and paper industry.

Huatao company could offer app most spare parts for Andritz S series ,Sulzer APP/CZ/SNS/NPP/A series spare parts. Weclcome contact us for inquiry

can not be empty

can not be empty