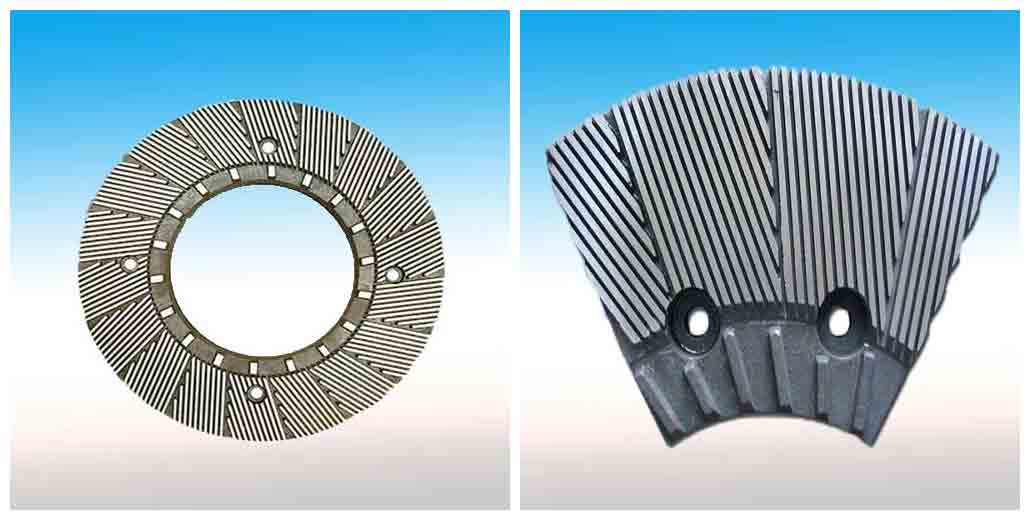

Huatao can produce various over one hundred of refiner plate with fine patterns teeth,which features in exceptional strength and durability for all fiber types.

Huatao refiner disc include conical refiner disc,double disc refiner,heat refiner disc, dispersing machine refiner disc, hot dispersing refiner disc, etc.

The pulp beating disc refiner plate is the "heart" of the disc refiner and the cone refiner.

In addition to the need for excellent wear resistance and impact toughness, the rationality of the tooth profile will directly affect the beating performance. "Three points for paper making, seven points for beating", to process different slurries, different indexes and the number of refiners in series should choose different tooth types. Therefore, the study of the relationship between the theory of specific blade edge load, the theory of specific surface load, rheological effect and beating performance, and the non-isolated understanding of the relationship between the various elements, is important to ensure the fiber bonding strength, filter performance, retention rate, quality of the finished paper and It is very important to save power consumption for beating.

Our refiner disc can perfectly match with various leading refiner brands in the world.

Material:

The refiner plate is designed with an appropriate tooth profile to achieve the established beating parameters and has good wear resistance and impact toughness.

Our material ranges from alloy,cast iron chrome coated,17-4PH,medium carbon S.S/ special S.S,high carbon S.S,etc

Main Technical Parameters:

|

Product Name |

Refiner Disc |

|

Type |

Whole circle type,Segment type |

|

Model |

250 - 800 |

|

Diameters |

300mm - 2083mm |

|

Hole |

4 - 8 |

|

Installation hole distance |

1000mm |

|

Thickness |

25mm - 40mm |

|

Hardness |

35 - 60 |

|

Inner Diameter |

700mm |

|

Applied Refiner Machine |

Andritz,Valmet,Voith,GL&V,Cellwood,etc |