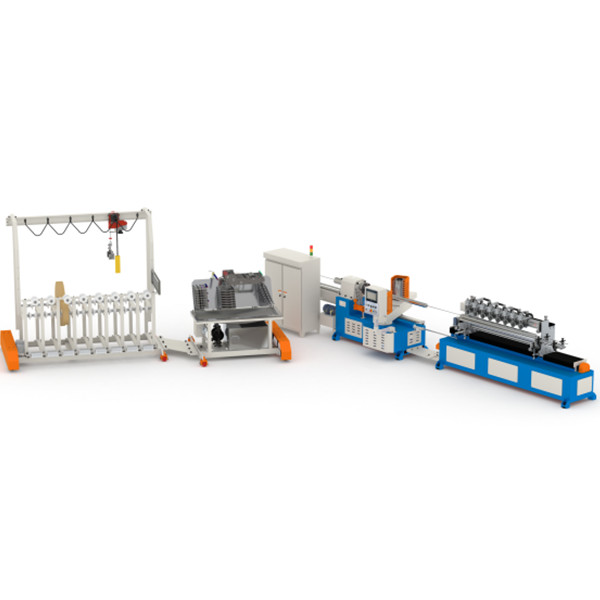

Multi blade Spiral Paper Tube Machine HT23-120

These machines are industrial machines that spirally wrap paper or cardboard into pipes. This type of machine is used in the production of pipes of different thicknesses and sizes.

Usage:

Standard production of 3-inch paper tubes (inner diameter 76.2mm) with a thickness of less than 3mm, maximum

production of paper tube inner diameter120n

Mainly used for producing paper tubes with sma

aller diameters and shorter lengths, it can complete multiple segments

of cutting at once.

Production use reference: can body for packaging composite round cans, paper cores for small packaging materials

winding, and office roll paper core tubes

The production of spiral paper tubes is c

completed in one go from gluing, winding, to cutting according to requirements.

Feature

1. Equipped with a multi blade cutting device, it can cut the finished product in one go for shorter paper tubes, eliminating

the need for secondary cutting processes.

2. The main body is made of thick and heavy steel plates, which are welded after CNC cutting. The frame is stable and

not easily deformed, with low vibration.

3. The main transmission adopts hard tooth surface full oil bath gear reduction, low noise, low heat generation, high

speed, and high torque.

4. The main motor adopts a vector type high torque frequency converter for speed regulation

5. Equipped with a hydraulic belt tensioning device, equipped with a belt tension sensor and a belt angle sensor, which

Equipped with ENC synenronous iuting system, the cting table is driven by precision ball screws and high-

5. Equipped with a CNC synchronous cutting system,

performance servo motors.

7. Equipped with pulse length control and feedforward compensation function, it ensures consistent cutting length at

different operating speeds of the host.

8. Adopting a multi PLC control system, IO output control and functional operation are separately controlled to improve

cutting response speed, and cutting length control is more accurate than before.

9. Configure a new type of operation panel and a large-sized color touch screen human-machine interface for operation.

10. Equipped with a multifunctional bottom paper supply device and automatic paper cutting stop function.

11. Equipped with an integrated paper stand, glue stand, and paper guide device, fully electrically adjustable

2. Modular electrical layout design makes use, maintenance, and repair more convenient and scientific.

13. Equipped with a network module, it is used for multiple devices or pipeline networking, and can also be used for

remote monitoring and maintenance, MODBUS TCP and MQTT protocols.

14. Optional pneumatic paper tension device.

15. Optional automatic paper splicing device.

16. Optional integrated electric synchronous pull rod device.

17. Optional aluminum foil heat sealing device and mold water cooling device are available for the production of sealed

composite cans.

18. Ooptional length automatic adustment tool holder, standard with 5 sets of tool holders, (when selecting automatic

adjustment tool holder, 4 sets of electric tool holders and 1 set of manual tool holder).

19. Optional color detection device can detect precise

position cutting of labeled paper tubes.

|

Parameter |

|

| Number of layer | 3-8 layers |

| Max-inner diameter | 120mm |

| Min-inner diameter | 20mm |

| Max-thickness | 3mm |

| Min-thickness | 0.8mm |

| Way of Mandrel fixing | Flange & tightening |

| No of winding nose and belt | Two noses and one belt |

| Way of cutting | pneumatic ,5 sets circular cutter |

| Way of glue feeding | Double sides |

| Way of length locating | Encoder |

| Operator | 1-2 Person |

| Production speed | 3-20M/Min |

| Speed control | Inverter |

| Input power | Custom |

|

Size(mm) |

|

| Mainframe:L*W*H | 6300mm*1700mm*2000mm |

| Area: L*W | 16000mm*7000mm |

| Wheel hub diameter | 215mm |

| Wheel hub height | 400mm |

| Min tread | 750mm |

| Max tread | 950mm |

| Total weight | 4200Kgs |

|

Drive system |

|

| Mainframe power | 7.5KW WANNAN |

| Max rotating speed of wheel hub | 47R/Min |

| Wheel hub output torque | 1360N.M |

| Chain type | 12A*2 |

| Wheel hub type | 2 wheels |

| Bearing | WANXIANG |

Welcome to contact with us for machine runing video!